This is where we left off with windows. Now here’s where we pick up… The problem with just-in-time construction is it doesn’t allow for falling behind.

Tuesday we tried to stay ahead of the window and door installers by at least one opening. Here’s Joe applying house-wrap over the new foam+plywood and frames on the upstairs portion of the back wall…

Joe installed the custom flashing, bending it up at the inside corners and then sealing it down with super-duper tape…

Tape? For obvious reasons, you don’t want to put any fasteners through flashing — water has a way of getting into places you thought it couldn’t. The trick to keeping it out is to seal everything from the bottom up in order to shed the water back out. Bad flashing details can trap water and then it’s perfectly happy to cause mold, mildew and rot — not something we want.

Next up: the two big fixed window frames. Waiting to go in, no glass in them yet…

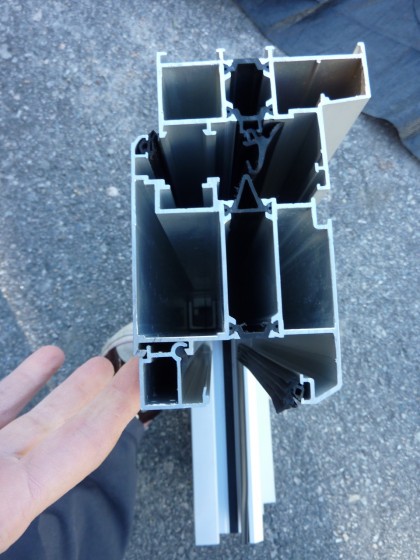

The aluminum window frames are thermally broken (they have a non-metallic connector between the inside and outside faces to limit heat transfer) but are ordinarily installed hollow. Joe and I decided leaving them hollow was a missed opportunity to be more energy-efficient, so I ripped 3/4″ EPS on the table saw to fit and we jammed it in there…

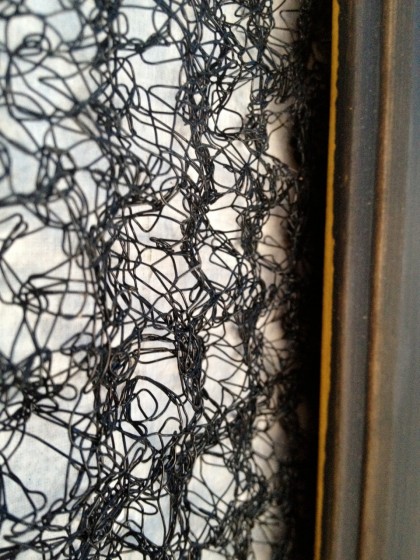

Once the window frames were installed level and square (which was easy because we made the extension frames level and square), butyl rubber got applied to the inside face of the frame…

Close-up of the frame almost ready for the glass…

I was an honorary glass man for the day, helping hoist the new panels into place with a fancy suction cup handle. Those suckers were HEHVEE….

Joe was the balance man…

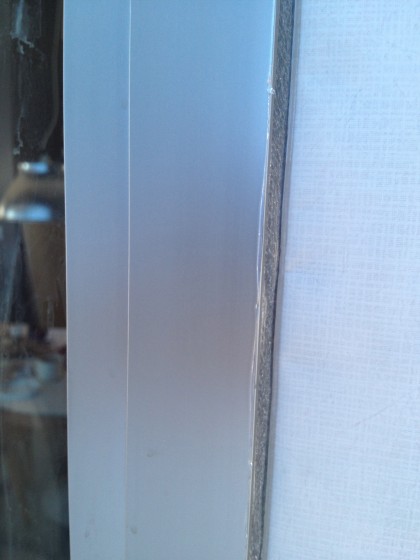

Once the glass was in against the butyl rubber, aluminum stops were snapped in on the outside and a rubber gasket was driven in-between the stops and the glass. No fasteners show so there’s a nice clean look.

That slot in the aluminum stop is a weep hole to let water out in case the wind drives it in there…

Each glass panel has a low-e coating on the inner piece of glass (“lite” in technical jargon). It acts as sort of a one-way system for radiant heat — heat from the sun can come in but can’t get back out…

The new sliders look great, perform great and slide like butter on a hot pan…

A bump stop goes in at the top of the slider to keep fingers from being crushed…

Digging the nice, clean look of the door hardware…

All in all, looking great from the outside…

But wait — not done yet! The gaps between the window and door frames and the house need to be filled. Caulk can bridge small gaps just fine but bigger gaps require that foam backer rod stuffed in. This stops the caulk from falling in to the gap…

Joe picked up a tube of this at Home Depot…

DO NOT use this. It stank to high heaven and smelled up the whole house even though it clearly says “V.O.C. compliant.” Not good. I’ll find something braincell-friendlier for the rest of the project.

So here’s the finished caulking job. The caulk is clear so it’s hard to tell what’s happening but I promise it’s in there. You can clearly see the backer rod!

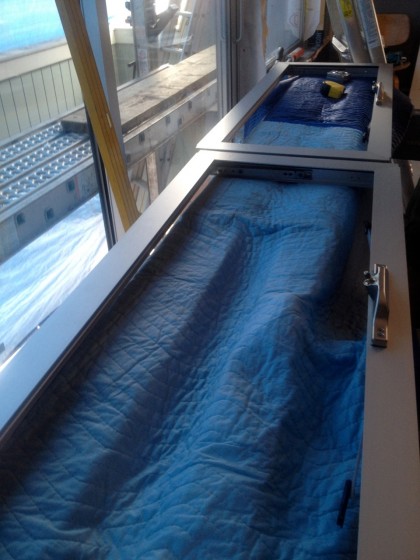

Backer rod didn’t fill the really big gaps at the tops of the two big windows so I put blue tape across them, pushed in a bit to leave room for caulk…

Then I filled all the gaps with expanding foam from the inside. The smaller gaps now have caulk or backer rod and caulk to stop the foam. The big gaps have the blue tape for the foam to expand up against. Soon I’ll strip the tape and caulk them from the outside, easy peasy.

And that, my friends, was a long day.