It’s been a while since we went to the bathroom together. David and Joe have been making progress on the built-ins in there, so maybe it’s time for a peek — even if it’s not quite done yet.

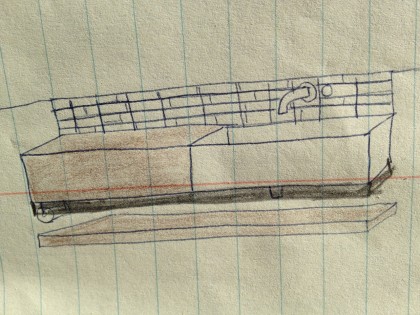

Let’s start at the beginning. A couple of years ago, I handed David a rudimentary scribble of what I pictured for our new bathroom vanity…

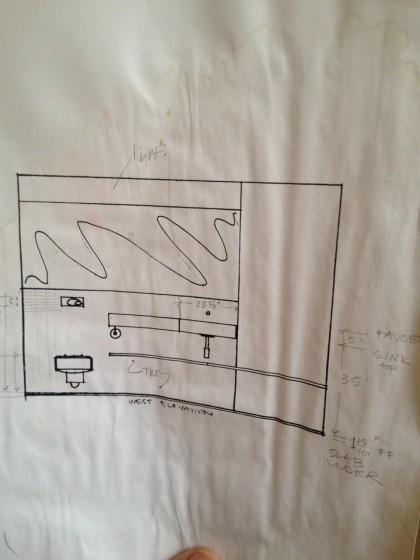

David drew it mo betta with measurements — I know I’ve shown you this before. This includes the shelf/bench and wall of walnut (to the right of the sink) that I was also hoping for…

Drawing is SO much easier than building. Here comes the hard part.

First, there was figuring out the complex, irregular curves of an imperfect sink — not as right-angled as woodworker might hope — in order to get the wood to mate up with it…

Required some math but they figured it out, as I trusted they would. So they continued on to constructing the vanity box…

The open end will face the toilet. That’s where the toilet paper and the occasional book or magazine will hide to keep things from getting messy.

Once that was done, they propped the vanity up on sawhorses and made sure it fit the space as intended with the sink and the faucet roughly in place…

There was the tricky veneering stage…

And then they secured to the wall and made the necessary tweaks…

They stained it in place. Here it is with two coats — it still has to be made waterproof (that’s another story)…

Just to the right of the sink is the walnut panel that will eventually have three hooks on it for hanging up clothes…

The bench/shelf that extends from below the sink still needs to be built. But isn’t that gorgeous?!

In that same corner there’s now the built-in linen cabinet that David began last June. Just look at that walnut! Love love love. Just needs a little tweak on that bottom drawer and it’s good to go…

Love how the minimal fingerpulls worked out. Perfect…

Inside, there’s plenty of room for towels and any bathroom paraphernalia…

There’s even a recharging station for an electric shaver! So spoiled…

The drawers are nice and deep…

Yes, the back of the cabinet and the drawers are angled to accommodate our angled wall. This should give you a better idea of the wall when you look at the other side. See how the lights are on angle, too?

Btw, that’s the record storage wall, in progress. More on that another time.

So, back to the bathroom. Here you can begin to get an idea of how the walnut built-ins will look together — in an outage. I need light!

Argh. So impossible to take decent pictures in this tiny bathroom — especially when the lighting isn’t done yet. Oh well.

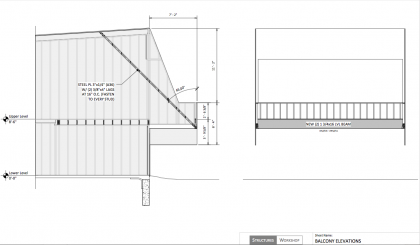

Before I go, take a peek at the fantastic custom pocket door David and Joe designed, built and installed…

A better look at the door project next week. That’s it for now.