David will now show you how we’re getting closer to having a bathroom downstairs…

—————————————————————————————————

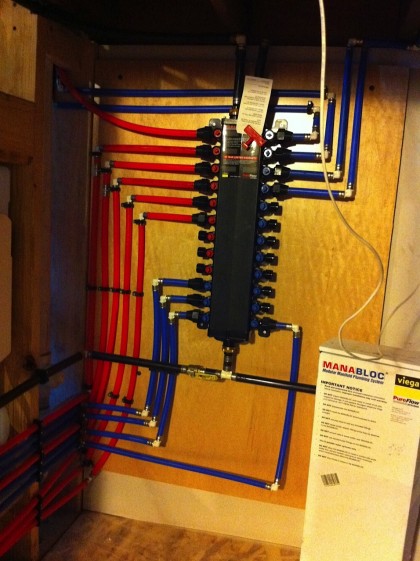

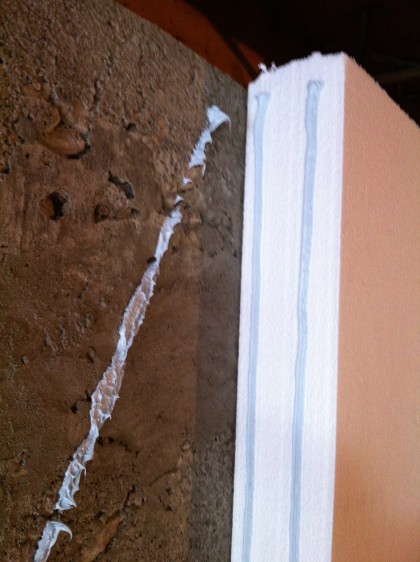

Things are really moving along down here. Once the bathroom framing was done, the plumber came in and ran all-new plastic pipe…

Rather than the traditional branch-style method of piping, with one shut-off for the whole house and individual shut-offs near some fixtures (but not usually all fixtures), we opted to have a manifold (think breaker panel for water) with all the piping in a home-run configuration. This means every fixture has its very own feed direct from the manifold and its very own shut-off…

Each of those little red and blue circles down the sides of the manifold is a shut-off. Eventually they’ll get labels so we know which is which.

There was just a sliver of space between our old, floor-mount toilet and the shower, so we’re going with wall-hung to gain some space back. That’s the precursor to our new Duravit wall-hung toilet on the left — its slim Gerberit tank (jah, German) hides away inside the wall framing…

The sink faucet rough-in with drain below is on the right.

For the faucet above the sink, we also chose wall-mounted. You can’t resist playing with it when you open the box, it’s so cool….

Modern. Simple. Not a bunch of fuss.

Then there’s the shower. Remember what it used to look like? Now we’re going for a much more minimal look. No more tub and the shower will have a partial glass wall with an open doorway for stepping in.

Brook wants a teak grid in the shower, so we went with this for the floor below it…

The shower pan will save us big over having to create a tile shower floor. Comes already sloped for drainage…

The plan is that the removable teak grid will sit inside the pan and look somewhat like this…

In fact, that’s pretty much the same idea we’re using for the glass wall, too. Should look very swank when it’s all said and done. Speaking of which, I should probably get it said and done right now!